BACKGROUND

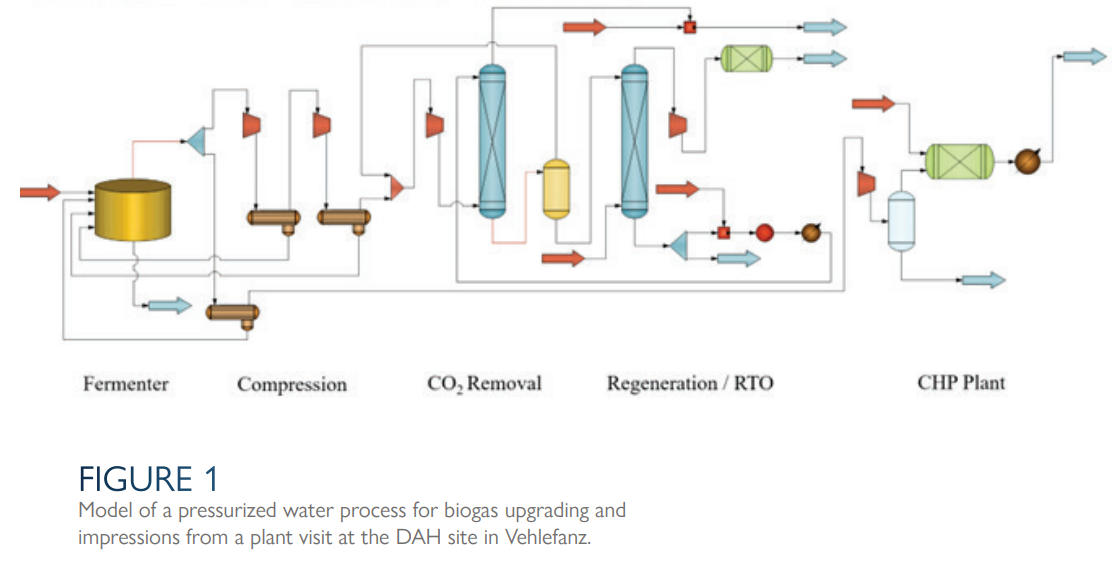

At the Berliner Hochschule für Technik in Berlin, Germany, students in their final semester of undergraduate studies take a course called Facility Design and Simulation. In this course, students use CHEMCAD process simulation to design a biomethane gas treatment plant and create related engineering documents, such as mass and energy balances, process flow

diagrams, equipment lists, and equipment specification forms.

After a brief introduction to the basics of flowsheet simulation, students use CHEMCAD to calculate mass and energy balances for their process. Once the basics are understood, students can adjust the operational parameters and optimize the process’s operating expenses (OPEX). With a fixed set of design variables, they then size the main equipment and estimate the capital expenditures (CAPEX).

CHALLENGES AND SOLUTIONS

One of the biggest challenges in undergraduate chemical engineering education is understanding complex subjects like thermodynamics. Even in senior-level courses, students may have gaps in their understanding and limited knowledge, which can hinder their progress in design courses. This is where CHEMCAD can help bring complex theory to life. By using CHEMCAD, students can apply their knowledge of engineering fundamentals to design feasible processes. Errors made

during simulation lead to a deeper understanding of the causes and effects of thermodynamic selections. Students will also see how the right thermodynamic models can simulate accurate mass and energy balances.

Additionally, the equipment sizing and economics tools in CHEMCAD help students determine whether, for example, utility consumption is too high for an economically feasible process. This capability is essential in engineering education because, in the real world, ensuring economic feasibility is a significant part of an engineer’s responsibility.

ELEMENTS OF SUCCESS

In a small class competition, students compete to find the process parameters that result in the lowest OPEX. They can compare whether the final costs they estimated for their project align with data from real-world plants in operation.

The highlight of this course is the excursion to a real plant, where students can see firsthand the scale of the equipment required to transport 1,000 cubic meters of biogas per hour. Incorporating hands-on experiences like plant tours and process simulation helps bridge the gap between theoretical knowledge and real-world application, preparing students for successful careers in engineering.