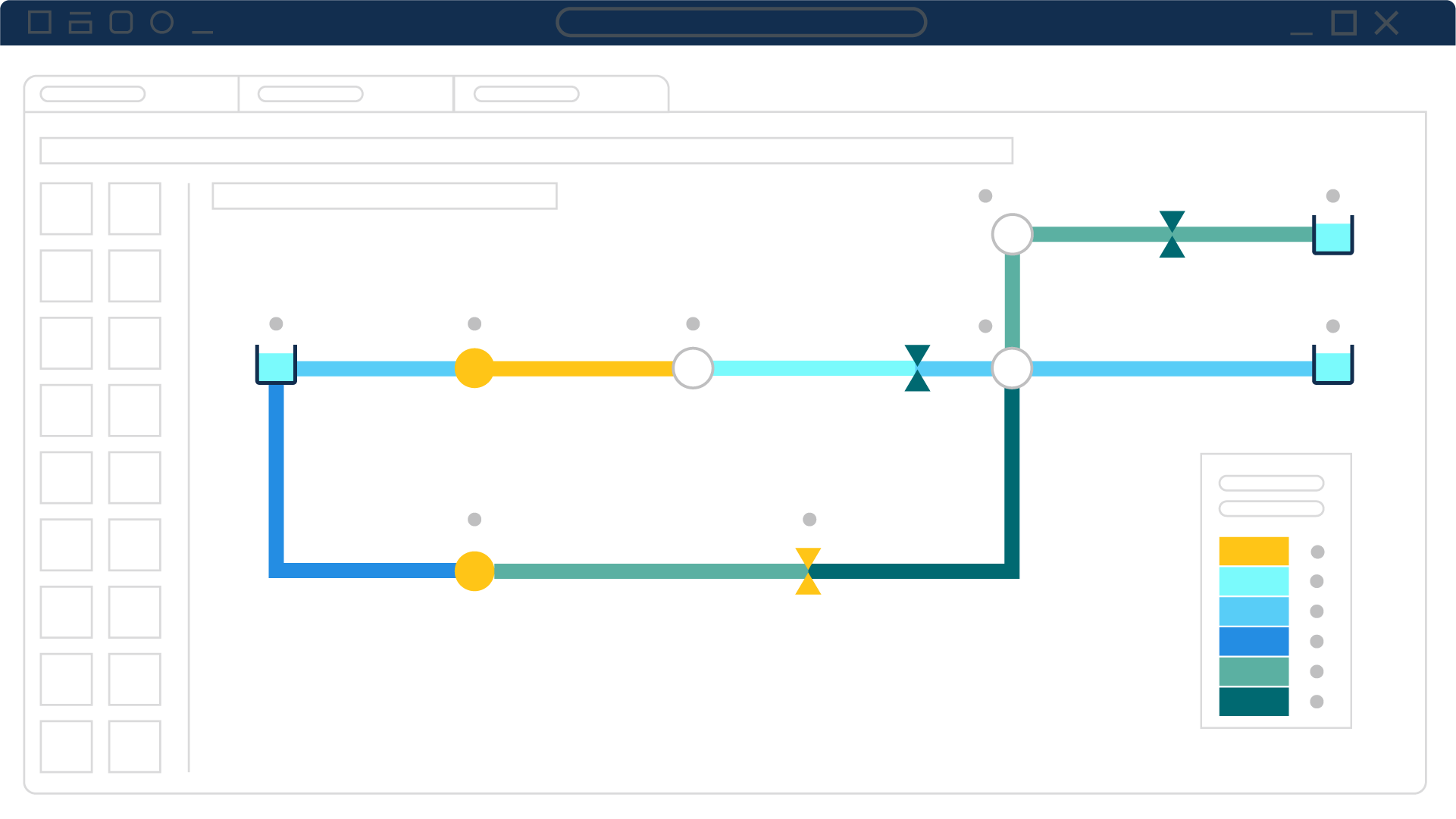

Water hammer & surge analysis software

Calculate pressure surge transients in pumping systems. Ensure pressure extremes stay within design limits and troubleshoot operational issues before they happen.

You need accuracy

Calculate pressure surges and size equipment to safeguard your system.

Track multiple “What-If“ operating cases within one file and compare multiple transient scenarios in seconds.

Animate events and export clear graphs and data for quick insights.

Developed by Engineers, for Engineers

Transient Surge Solver & Physics

Predict pressure surges, flows, and forces during water hammer events with an MOC-based transient solver.

- Models cavitation and column separation.

- Handles event- and time-driven operations (valve closures, pump trips/restarts, ESDs).

- Accounts for wave speed and system elasticity.

- Visualizes results with animations and pressure/flow/force plots.

Pump & Valve Transient Modeling

Capture real equipment behavior during trips, reversals, startups, and control actions.

- Centrifugal and PD pump transients with pump inertia/driver torque and four-quadrant curves.

- NPSH checks and check valve dynamics to mitigate slam.

- Time-dependent valve characteristics (Cv/Kv vs. time, open % vs. time, K-factor vs. time) and control valve logic with rate limits.

- Relief valve modeling with opening profiles and setpoints.

Surge Protection & System Devices

- Design alerts to enforce allowable pressures and velocities.

- Compare device sizing, setpoints, and locations across scenarios.

- Optional modules for pulsation (API 674 checks) and slurry water hammer.

Workflow and Integration

Build, manage, and share models efficiently—and connect results to stress analysis.

- Scenario Manager to track alternatives in one file.

- Excel import/export for model data and results.

- Import piping from CAESAR II® Neutral files, PCF files, and GIS shapefiles.

- Export transient forces to CAESAR II®, TRIFLEX®, ROHR2, and AutoPIPE.

Visualization & Reporting

- Animate pressure waves, flows, and levels; apply color maps on the model.

- Create time-history graphs, max/min envelopes, and cross-plots.

- Export output data, animations, workspace models, and report-ready graphs.

Fluids & Property Libraries

- Standard Fluids, NIST REFPROP, and ASME Steam Tables included; optional Chempak (~700 fluids with mixing).

- Support for temperature-dependent properties and user-defined fluids.

- Non-Newtonian options (e.g., Power Law, Bingham Plastic, Herschel-Bulkley) for specialty applications.

Model Initialization & Operating Limits

- Automatic steady-state initialization with reservoirs, control valves, and time-varying boundaries.

- Elevation profiles and partially filled pipe ends where systems drain between runs.

- Design alerts for pressure, velocity, NPSH, and other engineering limits.

Settling Slurry (SSL Module)

- Model both settling and non-settling slurry transients.

- Account for solids concentration effects on density, viscosity, and acoustic wave speed.

- Apply slurry-specific friction correlations to estimate pressure loss and energy requirements.

- Evaluate pump performance and NPSH under slurry conditions; assess derating needs.

- Optimize pipe diameter and target velocities to reduce deposition or erosion risk.

Pulsation Frequency Analysis (PFA Module)

- Build an acoustic model to calculate natural frequencies.

- Check peak-to-peak pulsation against acceptance limits (e.g., API 674).

- Size and place pulsation control devices (accumulators, volume chambers, orifices).

- Identify resonance risks in header/branch configurations and verify mitigation across the operating range.

- Use spectral plots and envelopes to compare alternatives and document compliance.

Validation

Confirmed safe transient behavior after pump removal.

Learn More

Evaluated surge in an 11-story data center.

Learn More

Adjusted control valve closure reduced surge; eliminated relief valve chatter.

Learn More

Eliminated vacuum conditions and confirmed pressures to reduce unplanned shutdowns

Learn MoreWho We Serve

Datacor Pipe Flow Modeling is built for professionals who design, analyze, and operate complex fluid systems.

From plant engineers to consulting firms, Datacor Pipe Flow Modeling Solutions empowers users to optimize performance, troubleshoot issues, and ensure safe, efficient operations. If your work depends on understanding and improving piping and fluid flow systems, Datacor is your trusted partner.

Questions?

Does Impulse model cavitation and column separation?

Can Impulse simulate gas transients?

How are pump transients handled (trips, restarts, reverse flow)?

Can I model non-Newtonian fluids or pulp-and-paper systems?

Can Impulse model partially filled pipes?

Can I set operating limits and use elevation profiles?

How does Impulse’s steady-state differ from Fathom?

Impulse uses the same steady-state method but only for water hammer initialization. It does not analyze heat transfer, and has no pump/system curve graphing.

Because they share the same code-base and interface, you can easily transition your Fathom model to Impulse simply by opening the Fathom file in Impulse and saving it.

What fluid property databases are included?

Impulse Resources

Explore More Resources

You may also be interested in

Calculate steady-state hydraulic pressure drop and pipe flow distribution in liquid and low-velocity gas piping and ducting systems.

Steady-State Compressible Flow Modeling. Calculate pressure drop and flow distribution in gas and steam systems

Dynamic simulation tool for high-speed, acoustic transients that occur in steam and gas piping systems.

Robust chemical process simulation software designed to meet the diverse needs of engineers who design, troubleshoot, and innovate.