Built to digitize operations, boost productivity, and ensure quality

Trusted by process manufacturers to track production in real time, reduce waste, and maintain quality and compliance.

Unlock the full potential of your plant floor

Maximize throughput using existing resources. Reduce cycle times, eliminate waste and downtime, minimize rework, and empower operators with real-time data to boost OEE.

Built-in validation, PPE alerts, and in-line quality checks ensure safe, compliant production. Proactive monitoring helps prevent errors, maintain standards, and deliver consistent quality every time.

Connect people, processes, and systems across the plant floor to enable real-time collaboration, streamlined execution, and informed decision-making.

Designed for your needs

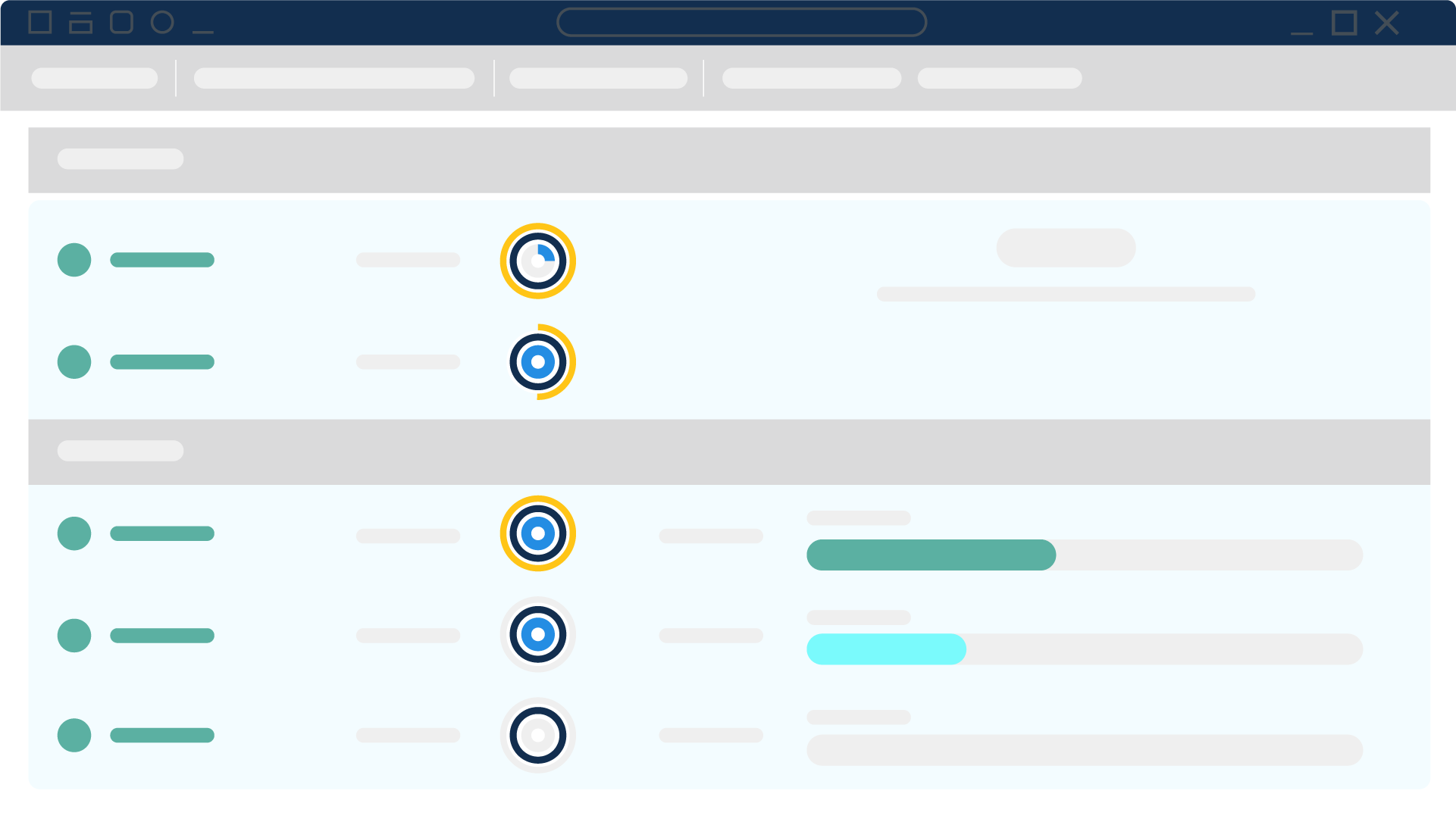

A fully digital shop floor

End-to-end traceability and quality assurance

Real-time production tracking

Built-in validation and safety controls

Actionable insights for continuous improvements

Seamless ERP integration

Mobile-first functionality

Results

Explore Customer Stories

Digitized production to reduce manual work, improve traceability, and boost productivity.

Learn More

Real-time data and digitization drove safer, smarter manufacturing at Hubbard-Hall.

Learn More

Digital batch tickets enabled real-time planning and reduced manual errors.

Watch VideoWho We Serve

Datacor MES is the execution system of choice for process manufacturers and chemical distributors who demand real-time control, less waste, and more efficiency on the plant floor.

Whether you’re running a specialty chemicals plant, food manufacturing line, or private label operation, Datacor MES helps you streamline production, ensure compliance, and deliver consistent quality at scale. Backed by Datacor’s decades of industry focus, we’re your partner in operational excellence.

Questions?

What is MES software?

How does MES improve production efficiency?

Can Datacor MES help reduce manufacturing waste?

How does MES improve inventory accuracy?

Is Datacor MES difficult to use?

Does MES support regulatory compliance?

How does MES integrate with other systems?

MES Resources

Explore More Resources

Learn more about how Datacor MES improves visibility, quality, and performance across operations.

You may also be interested in

Unified command center connecting inventory, production, quality, finance, and compliance in a single source of truth.

Real-time lot tracking and warehouse automation for audit‑ready traceability and near‑perfect inventory accuracy.

A secure R&D sandbox for rapid recipe iteration, cost estimation, and version control to speed time to market.

Automated SDS, GHS, and compliance tracking that keeps R&D, production, and documentation aligned with global regulations.

Easily generate compliant nutrition labels and ingredient statements to support transparency and meet regulatory requirements.

End‑to‑end container lifecycle tracking to reduce loss, automate rentals, and enable recall readiness.

Centralized customer insights, pricing, and quoting anywhere your sales or service teams work.

Intuitive, rigorous modeling to scale processes and cut CAPEX/OPEX before you commit capital.

Precise piping and surge analysis to optimize energy use and protect equipment.