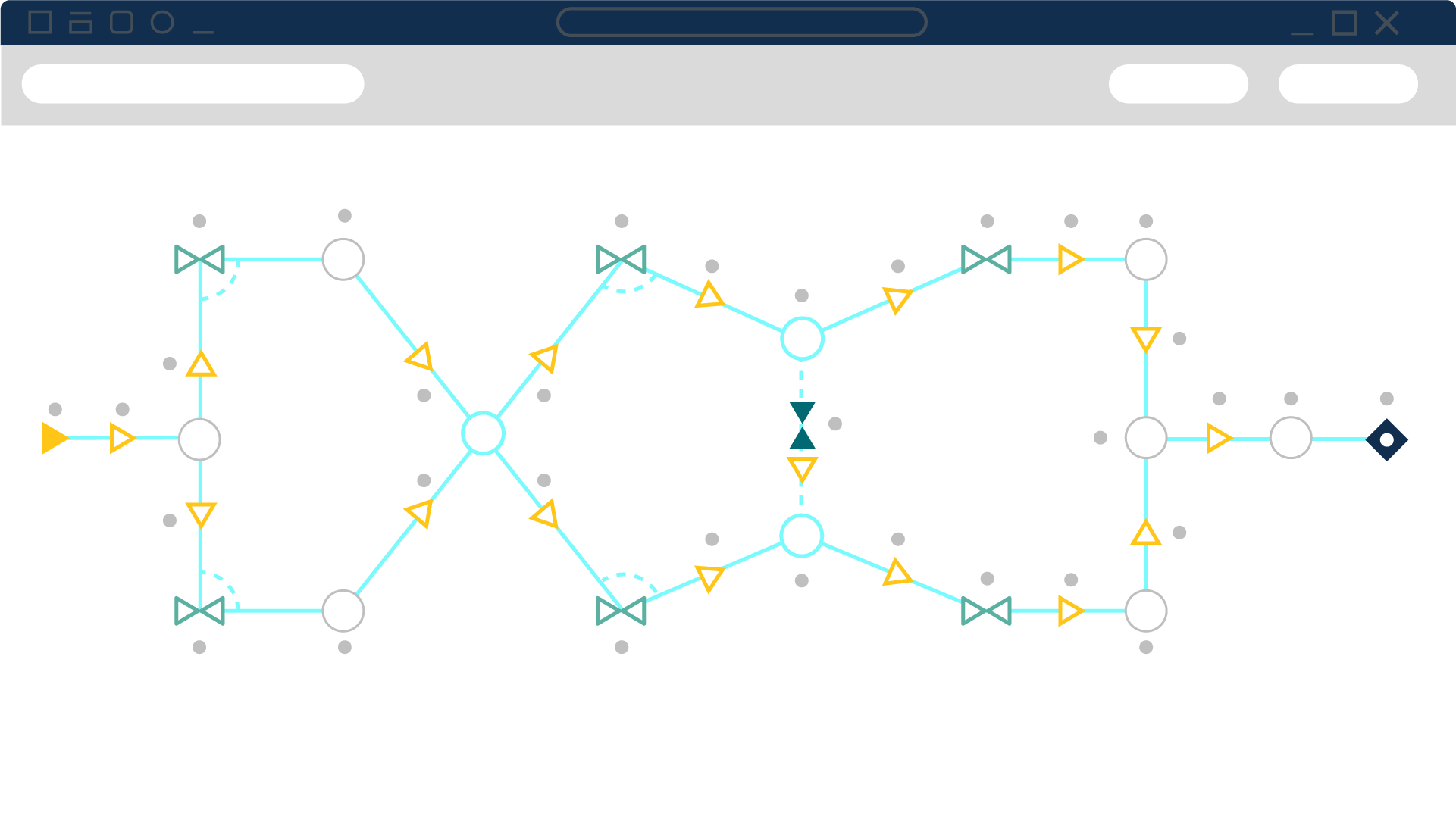

Calculate steady-state compressible flow pressure drop and flow distribution

Design, size, and optimize compressible gas and steam networks. Balance flows, reduce power, and verify performance.

You need accuracy

Predict pressures, temperatures, velocities, and Mach flows (subsonic through choked) across pipes/ducts, fittings, valves, and heat transfer for designs you can defend.

Evaluate fans/blowers/compressors with curve-based models, compare damper vs. speed control, and quantify power to meet delivery targets at minimum energy.

Diagnose issues with color-mapped results, ΔP/energy breakdowns, and choke flags, then export configurable reports and Excel data for fast, defensible reviews.

Developed by Engineers, for Engineers

Compressible flow solver & heat transfer

Model gas and steam networks with accurate compressible-flow physics.

- Subsonic to choked flow through pipes, ducts, fittings, valves, orifices, and nozzles

- Tracks pressure, temperature, density, velocity, Mach number, and Reynolds number

- Measure heat transfer along pipes/ducts and across equipment with temperature-dependent properties

- Real-gas property support and user-defined fluids for specialty applications

Fans, blowers, & compressors

Evaluate equipment performance and operating strategies across system states.

- Curve-based modeling with variable speed, control points, and staging (series/parallel)

- Predict delivered flow, head/pressure rise, power draw, and operating efficiency

- Compare operating scenarios (e.g., damper vs. speed control) to reduce energy use

- Identify operating limits, such as the approach to choke or insufficient head/pressure rise

Valves, regulators, & relief devices

Size and analyze control and safety components in compressible systems.

- Time or condition-based control valve actions; characterize Cv/K vs. opening

- Choked-flow evaluation through valves, orifices, and restrictions

- Pressure-regulating and back-pressure devices for stable setpoint control

- Relief device capacity checks and setpoint trade-offs under multiple scenarios

Workflow, reporting, & integration

Build, compare, and share models efficiently across teams.

- The Scenario Manager tracks alternatives in one file for easy comparison.

- Import/export Excel data for model data and results or to configure reports and graphs

- Import piping/duct layouts from PCF, CAESAR II® Neutral files, EPANET, and GIS shapefiles

- Design alerts for allowable pressures/velocities and color-mapped result visualization

Network balancing & distribution

Balance flows and pressures across branching gas/steam networks to meet equipment and process setpoints.

- Tune dampers, orifices, and regulators to hit target flow/pressure in each branch

- Assess parallel-path interactions and recirculation; verify minimum delivery at users

- Compare damper vs. speed control strategies for distribution and energy impact

- Identify bottlenecks with ΔP breakdowns, color-mapped results, and sensitivity checks

Goal seek & control (GSC module)

Automatically adjust inputs to meet engineering goals and constraints.

- Solve for fan speed, damper position, regulator setpoints, or nozzle area to hit flow/pressure/velocity/temperature/Mach targets

- Link multiple controllers with priorities, bounds, and constraints to avoid infeasible solutions

- Find solutions that meet multiple system requirements by analyzing multi-variable conditions of equipment

- Prototype control strategies without manual iteration

Extended time simulation (XTS module)

Simulate time-dependent behavior in compressible networks.

- Model startup/shutdown, purge/pressurization, and blowdown with scheduled events and ramps

- Track time histories for pressure, flow, temperature, and Mach; animate network response

- Sequence equipment staging (fans/compressors) and control actions over time

- Check operating limits under transients and evaluate recovery to steady targets

Automated network sizing (ANS module)

Optimize pipe/duct sizes and equipment selections to meet constraints at minimum cost or power.

- Constrain flow, pressure, velocity, Mach, and ΔP at critical nodes and branches

- Minimize capital cost, weight, or operating power using configurable cost models

- Pick from standard size catalogs or continuous diameters with constructability rules

- Output a sized bill of materials and compare alternatives with Scenario Manager

Modeling showed VFDs with open dampers cut fan power 25–30% across states.

Learn More

Verified lower setpoint increased flow and avoided upgrades.

Learn More

Field-correlated model confirmed the capacity for new customer commitments.

Learn More

Worst-case analysis kept pressure below relief

Learn MoreWho We Serve

Datacor Pipe Flow Modeling is built for professionals who design, analyze, and operate complex fluid systems.

From plant engineers to consulting firms, Datacor Pipe Flow Modeling Solutions empowers users to optimize performance, troubleshoot issues, and ensure safe, efficient operations. If your work depends on understanding and improving piping and fluid flow systems, Datacor is your trusted partner.

Questions?

Does Arrow handle sonic choking?

Can Arrow be used to model liquid systems?

How does Arrow account for real-gas effects and heat transfer?

What is the practical limit to model size?

Can Arrow model a turbine?

How does Arrow calculate losses at tees and wyes?

How do I model a relief valve (and choked flow through restrictions)?

How do I create gas mixtures or model dynamic mixing?

Pipe Flow Modeling Resources

Explore More

You may also be interested in

Calculate steady-state hydraulic pressure drop and pipe flow distribution in liquid and low-velocity gas piping and ducting systems.

Surge analysis software used to calculate high-pressure transients in liquid piping systems caused by water hammer.

dynamic simulation tool for high-speed, acoustic transients that occur in steam and gas piping systems.

Robust chemical process simulation software designed to meet the diverse needs of engineers who design, troubleshoot, and innovate.