SYSTEM

Fluid Quip Technologies (FQT), a global leader in Bio-Tech engineering, has spent over 30 years driving innovation and process solutions for the beverage, biofuels, and biochemical industries. When it came time to evaluate and optimize a critical distillation process, FQT chose CHEMCAD for its versatility and power in supporting this project’s complex process simulation requirements.

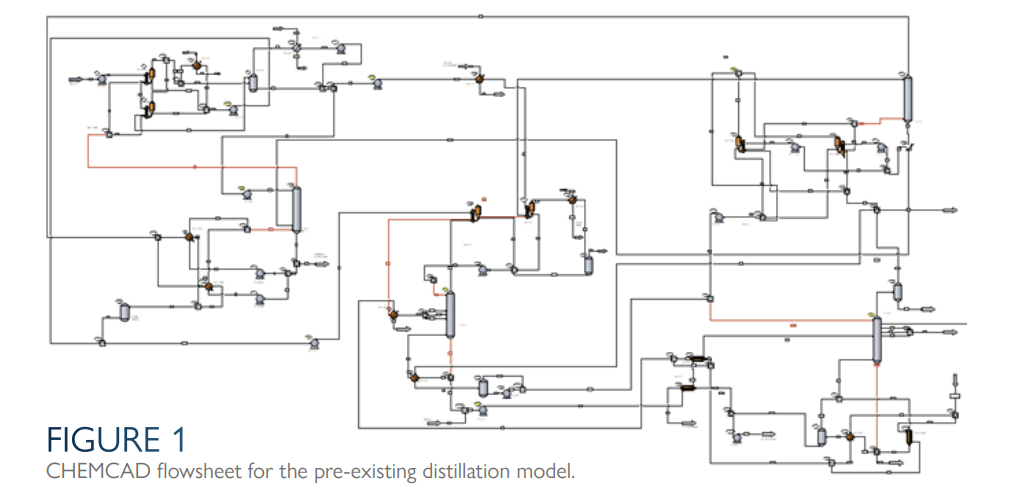

Using process data and equipment drawings from the existing process, FQT’s engineers built a steady-state simulation of the process in CHEMCAD. This simulation enabled FQT to explore opportunities to reduce energy consumption by re-designing the distillation system based on the existing equipment.

SIMULATION

The project was modeled using a combination of heat exchangers, distillation columns, and pumps. The primary goal of the simulation was to assess distillation column performance, focusing on tray compositions and liquid loadings to identify potential capacity bottlenecks. Using CHEMCAD’s advanced distillation column modeling and sizing tools, FQT successfully matched site specifications and optimized column performance. FQT also leveraged CC-THERM, a rigorous heat exchanger modeling tool included in the CHEMCAD suite, to accurately size both plate-and-frame and shell-and-tube heat exchangers, ensuring energy efficiency throughout the system.

SOLUTION

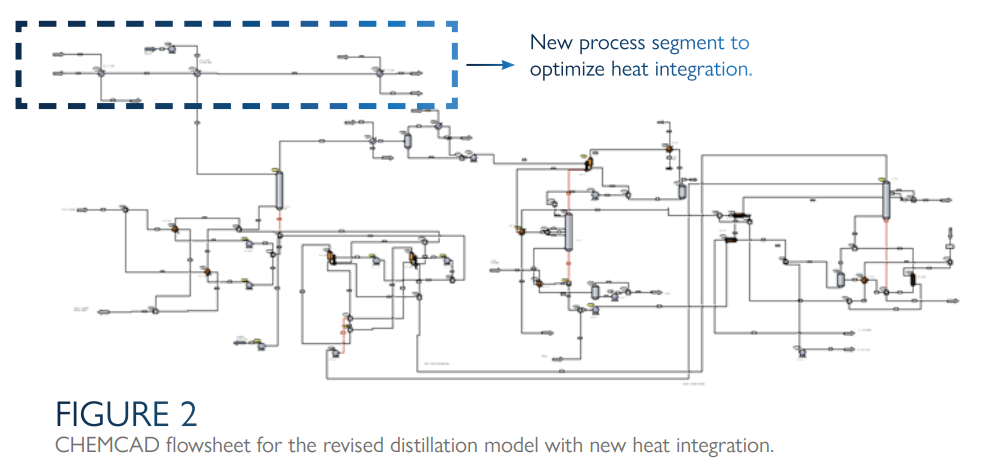

The results of this simulation helped to pinpoint columns with excessive tray loading. Using CHEMCAD’s internal column tools, FQT was able to test alternative tray configurations and quickly identify more efficient designs.

Knowing that column design was only part of the design puzzle, FQT also used the heat exchanger sizing tools in CHEMCAD to identify the limitations in exchanger capacity. After uncovering capacity limits, FQT made efficiency-driven adjustments to minimize steam usage in the distillation process. This approach allowed FQT to re-work the original flow path to achieve significant energy reductions, without requiring additional capital investment.

ELEMENTS OF SUCCESS

Starting from an established process with extensive heat integration already in place, CHEMCAD provided the detailed thermodynamic and component-level insights across the process that FQT needed to identify new cost savings and process optimization opportunities. This simulation played a key role in identifying further efficiency gains, reducing energy consumption, and enhancing system wide performance, demonstrating the power of CHEMCAD for solving complex, real-world process optimization challenges.