SYSTEM

Unted Kingdom based P&I Design provided consulting services to help their customer determine if their exisiting system could double the ethanol content in a gasoline blending system—from 5% to 10%. Using CHEMCAD, it was clear that the existing infrastructure would be insufficient. P&I design was able to find a cost effective and operationally sound strategy that would enable their client to achieve full-capacity blending, without compromising flow control or system performance.

SIMULATION

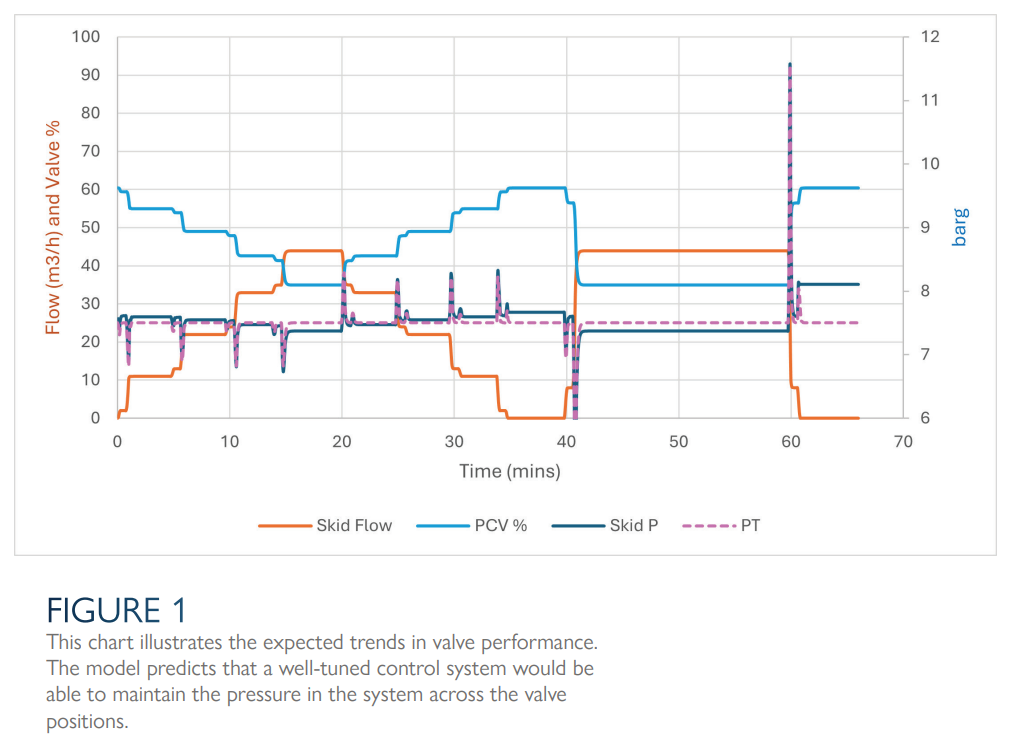

The system blends ethanol with gasoline while loading up to three road tankers simultaneously. Flow rate to the blending skids is controlled by the blending skids, and the remaining ethanol is spilled back to the tank of origin under pressure control. This complex interaction of flows and control elements was modeled using CHEMCAD’s built-in unit operations for pipes, pumps, controllers, and nodes. Using the CHEMCAD sensitivity analysis tools, the engineers at P&I Design were able to evaluate how the system performed under a range of different gasoline flow rates. Dynamic modeling was used by the team to simulate how the control system would respond to the changing flow rate.

The installed pressure control was only capable of loading 10% ethanol to a maximum of two arms simultaneously. The next step would be to determine the most efficient and reliable way to upgrade the system to meet the new blending

requirements.

SOLUTION

Simulation results predicted that increasing the pressure set point would result in improved control, however it would also increase the risk of damaging the pump. The pressure set point was increased as a short-term solution, allowing the

system to run at full capacity while a more robust pressure control system was designed and installed. Further modeling determined the recirculation pipe sizing and valve requirements, and dynamic simulation demonstrated how the control

philosophy would perform, using the selected manufacturer’s valve. The result was an optimized, safe, and cost-effective solution—successfully brought online with minimal disruption to ongoing operations

ELEMENTS OF SUCCESS

Using CHEMCAD, P&I Design was able to replicate the challenges experienced on site, providing clarity on both the limitations of the existing setup and the best path forward for short-term and long-term solutions.

Steady-state modeling was used to guide equipment selection, while dynamic simulation was used to demonstrate effective

control strategies under real-world conditions. From pinpointing bottlenecks to finding long-term solutions, CHEMCAD delivered the insight needed to save time, save money, and reduce risks for their client’s evolving fuel blending demands.