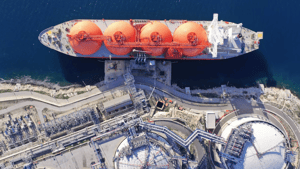

LNG

Predict Performance. Optimize Operations. Ensure Safety.

Engineering Simulation Tools

Datacor’s simulation software validates LNG upgrades, evaluates surge, and helps engineers design safe and efficient systems.

Modern chemical process simulation software designed with the engineer's workflow in mind to help efficiently identify innovative solutions.

Calculate steady-state hydraulic pressure drop and pipe flow distribution in liquid and low-velocity gas piping and ducting systems.

Determine the pressure drop and flow distribution, analyze sonic choking, and model real gases in steady-state gas and steam piping systems.

Analyze pumping systems for harmful pressure surge transients caused by water hammer.

Analyze high-speed, acoustic transients that occur in steam and gas piping systems.

Design LNG processes

Simulate transient events

Size and rate equipment

Evaluate steady-state pressures

Analyze surge and water hammer

Analyze compressible gas flow and relief networks.

Results

Explore Customer Stories

Validated expansion; surge held below design limits.

Learn More

New design removed vacuum risk, simplified system layout.

Learn More

Simulation kept loading-arm stresses within spec under ESD.

Learn MoreFocused Expertise

- Liquefaction

- Export Terminals

- Floating Storage

- Loading Arms

- Power Generation

Let’s see what we can achieve together

Contact UsLNG Resources

Explore More.png?width=300&height=170&name=AFT%20Blog%20(523x349).png)

.png?width=300&height=170&name=AFT%20Blog%20(523x349).png)

Industry Events We Attend